RECOMMENDATION FOR LIGHTWEIGHT FOAMED CONCRETE

One such LWC is foamed concrete. This property will help in completely filling the voids.

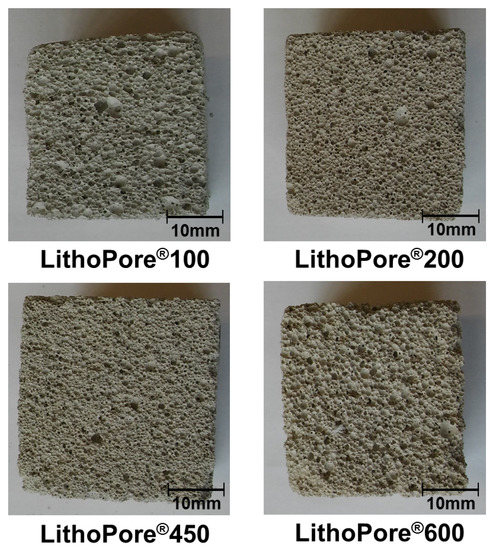

Applied Sciences Free Full Text Pore Characteristics And Their Effects On The Material Properties Of Foamed Concrete Evaluated Using Micro Ct Images And Numerical Approaches Html

Simply pour into place to the required level Topfoam needs no compaction has excellent insulating properties and can be delivered to site in conventional readymix concrete trucks.

. In this project to produce foamed concrete with high strength it was chosen to be 500 kgm3. This study is aimed to investigate the effect of eggshell powder on the engineering properties of lightweight foamed concrete with the density of 1300kgm3 with the tolerance of 50 kgm³ in terms of strength properties. Ad Extends The Service Life Of Concrete.

After subway tunnel shafts opened for excavation and ventilation C16 should be filled with concrete or soil. Lightweight Concrete Fill is an engineered geotechnical material with a unique strength density relationship which can be used to reduce loads on soft foundation soils buried structures or. The dead weight is reduced as it is light weight concrete.

Concrete Your Way In New Jersey - A Mobile Concrete Supplier Batch Plant. Of lightweight concrete is between 300 and 1850 KNm3. The range of wc ratio used were 05 045 04 035.

The foam formed is blended into the cementitious mortar or grout to produce the foamed quantity of necessary density. Up to 10 cash back Above 5 wt- of NS addition the density of the hardened foamed concrete decreased significantly. Concrete making future excavation possible.

Water Resistant Recyclable Reusable. LIGHTWEIGHT FOAM CONCRETE PHASE-I PROJECT REPORT Submitted by ANVER SHERIFA 080104201005 KARTHIKEYANS 080104201019 PRAVEEN PRASATHS 080104201035 in partial fulfillment for the award of the degree of BACHELOR OF ENGINEERING in. While this document may not address all of a projects specific details it provides information for construction.

The primary driver of Lightweight Foamed Concrete use instead of standard CLSM is load reduction. Foam concrete is a very fluid lightweight cellular concrete fill material produced by blending a cement paste the slurry or mortar with a separately manufactured pre-formed foam. Due to its closed cellular structure the water absorption of foamed concrete is very low.

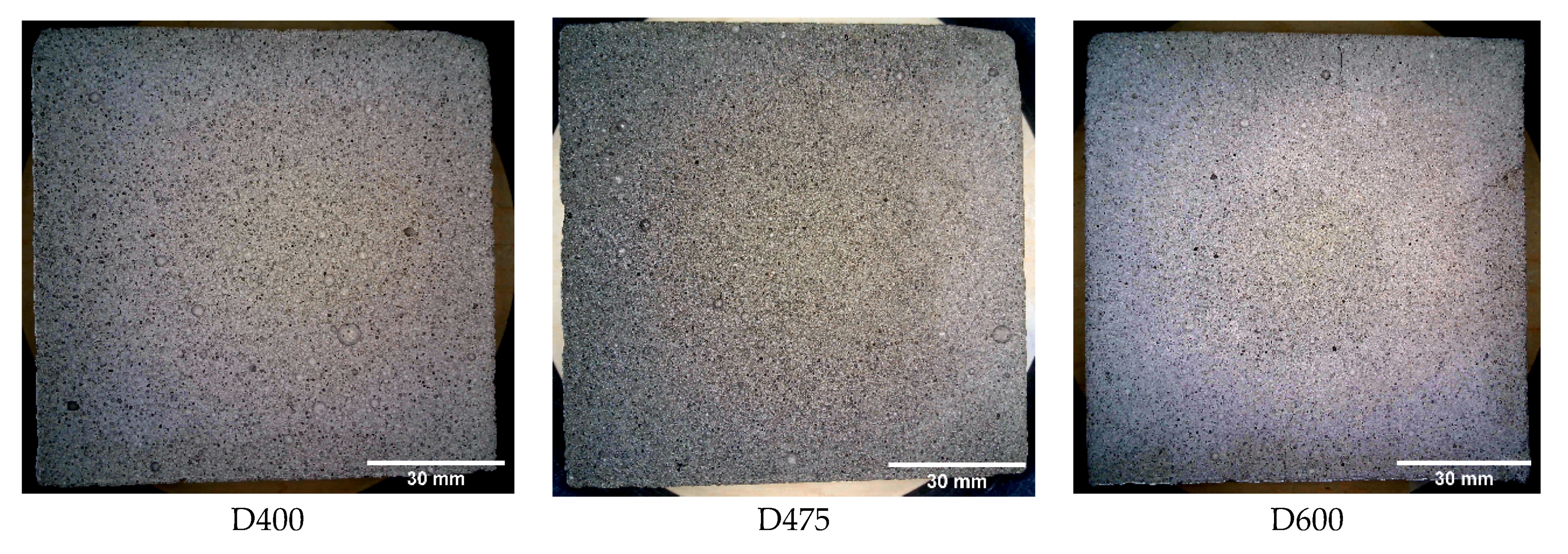

Most of the concrete mixes exhibited densities in the range of 350 50 kgm 3 which is an acceptable tolerance for lightweight concretes 8 11. Valore 1954 cement content in conventional foamed concrete with or without sand should be between 250 and 500 kgm3. Foamed concrete is known as light-weight or cellular concrete.

Foamed Concrete BREEDON Foam is a lightweight free flowing foamed concrete which has been specifically developed as an ideal trench reinstatement material to comply with the recommendations of the HAUC Highway Authorities Utilities Committee legislation. Fire rating of foamed concrete is far superior to that of brick work or dense concrete. Fresh density flow table drop average inverted slump diameter stability.

Lightweight concrete or foamed concrete is a versatile material which consist primarily of cement-based mortar mixed with at least 20 air by volume. FoamCrete 500 is an alternative filling concrete because of its lightweight and rapid application. Applications range from abandoning pipes to void filling below bridge abutments reducing loads on underground utilities and reducing.

It has high flowability low self-weight minimal consumption of aggregate controlled low strength excellent thermal insulation properties. Ideal Joint Filler For Footings Foundations Structures Curved Or Round Bases. Topfoam foamed concrete has been specifically developed for void fill.

The density of foam concrete is. Ad Find Deals on cement foam in Building Supply on Amazon. Introduction to Light Weighted Concrete.

The optimum mix proportion was designed based on target density wc and sc sand to cement ratio of lightweight foamed concrete. Reference 15 stated that based on previous studies Indian concrete Journal 1989. We Have What It Takes To Get The Job Done.

22 rows Light weight concrete is a mixture of cement water and special foam which. In addition to OPC rapid hardening PC high alumina cements can be used to reduce the setting times and. However higher the air content higher the water absorption.

The foamed concrete under its fresh state has freely flowing consistency. Topfoam foamed concrete is highly. The extremely lightweight foamed concrete contains only cement water and foam.

However the FA25 mix exhibited a higher density of 419 kgm 3. Ad Quality 1st Concrete Has 20 Yrs of Experience. Generally it is less than 5 percent by volume.

Foamed concrete prepared with waste materials also demonstrates improvement in thermal performance making it more sustainable. Lightweight foamed concrete LFC. The range of densities were 15001750 and 1800 kgm3.

PROPERTIES OF LIGHTWEIGHT FOAM CONCRETE Water Absorption. A light backfill is preferred especially if the tunnel passes under or near the shaft. The OPC is used with contents varying from 300 to 600 kgm 3.

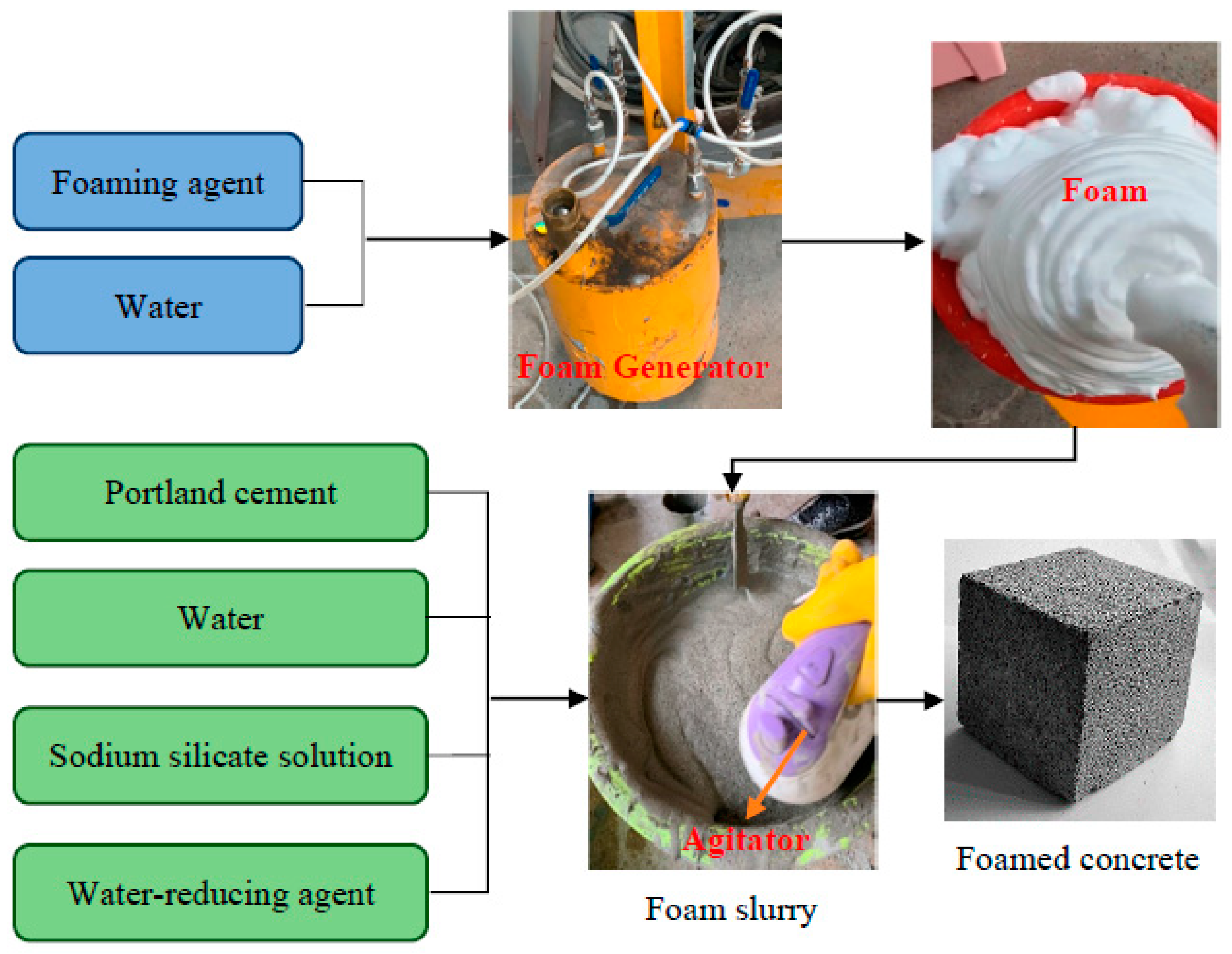

Foamed Concrete Does not impose significant lateral loads. It is commonly defined as a cementitious material with a minimum of 20 by volume mechanically entrained foam in the mortar mix where air-pores are entrapped in the matrix by means of a suitable foaming agent. The foamed concrete also known as lightweight concrete is made by diluting surfactants in water and running it through a foam generator which forms a stable structural foam.

Foamed light weight concrete in the form of bricks blocks or poured in-situ is used for thermal insulation over flat roofs or for cold storage walls or as non-load bearing walls in RCCSteel framed buildings or for load bearing walls for low-rise buildings. It shows excellent physical characteristics such as low self weight relatively. The foam concrete structure has excellent load spreading and distributing capability.

Guide to Lightweight Cellular Concrete for Geotechnical Applications provides information on the materials properties design proper handling and applications of lightweight cellular concrete LCC for geotechnical applications. Topfoam is a lightweight pumpable concrete to encapsulate pipework or conveniently fill voids. The raw materials used for the production of foam concrete are binding agent aggregates foaming agent and water.

Generally foamed concrete with low density about 6001500 kgm 3 and sufficient compressive strength 35 MPa can be produced by incorporating waste for non-load bearing applications such as in flooring wall panel etc.

Classification Of Foam Concrete Based On Percentage Spread Download Table

Preparation And Optimization Of Ultra Light And Thermal Insulative Aerogel Foam Concrete Sciencedirect

Pdf Experimental Production Of Sustainable Lightweight Foamed Concrete

Mix Proportions For Cement Sand Foam Concrete Mixes Download Scientific Diagram

Concept Of Structural Lightweight Foamed Concrete Used In This Study Download Scientific Diagram

Best Recommended Foam Concrete Pumping Height Is 6 Meters And 12 Meters For Polystyrene Concrete

Energies Free Full Text Study On Foamed Concrete Used As Gas Isolation Material In The Coal Mine Goaf Html

Materials Free Full Text Characteristics Of Lightweight Cellular Concrete And Effects On Mechanical Properties Html

Komentar

Posting Komentar